In the rapidly evolving world of solar technology, the choice of materials for solar panels plays a pivotal role in determining their performance, durability, and overall efficiency.

Among the various materials available, ETFE (ethylene tetrafluoroethylene) and PET (polyethylene terephthalate) have emerged as prominent contenders for flexible photovoltaic systems.

This article provides an in-depth comparison between ETFE and PET solar panels, considering key criteria such as material composition, flexibility, transparency, durability, temperature resistance, weight, cost, efficiency, applications, maintenance, and environmental impact.

Comparison Chart

This comparison chart of ETFE and PET Solar Panels will give you a quick reference. For more in-depth exploration of these topics, please keep reading.

Item | ETFE Solar Panels | PET Solar Panels |

Material | ETFE, a fluorine-based polymer | PET, a thermoplastic polymer |

Transparency | High transparency (up to 95%) | Moderate transparency |

Durability | Excellent durability, resistant to harsh weather conditions and UV radiation | Good durability but may degrade over time |

Flexibility | More flexible, suitable for curved or irregular surfaces | Flexible, but may not be as adaptable as ETFE |

Weight | Lightweight and flexible | Lightweight and flexible |

Temperature Resistance | Excellent resistance to high and low temperatures | Sensitive to high temperatures, may degrade |

Chemical Resistance | Resistant to chemicals and corrosion | Sensitive to certain chemicals and degradation |

Cost | Generally higher cost than PET | Generally lower cost compared to ETFE |

Applications | Often used in lightweight, flexible, and curved installations | Commonly used in less demanding applications |

Material Composition

ETFE solar panels are constructed using the ETFE film as the outermost layer. This material is renowned for its high chemical resistance, which makes ETFE panels suitable for harsh environments.

On the other hand, PET solar panels are composed of polyester, specifically polyethylene terephthalate. While not as chemically resistant as ETFE, PET remains a durable material with diverse applications.

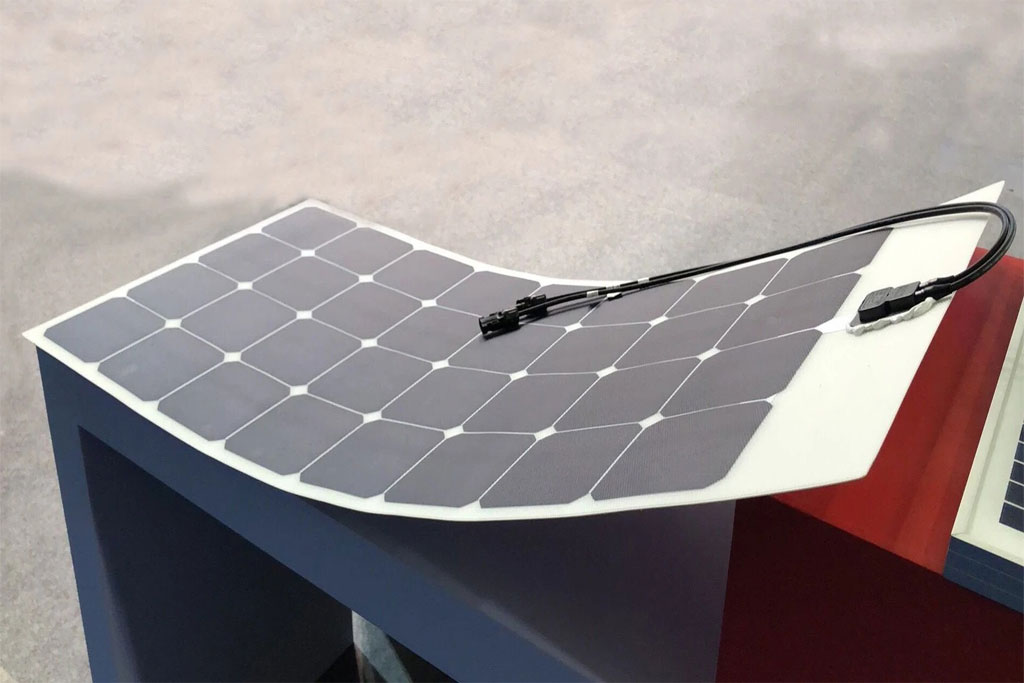

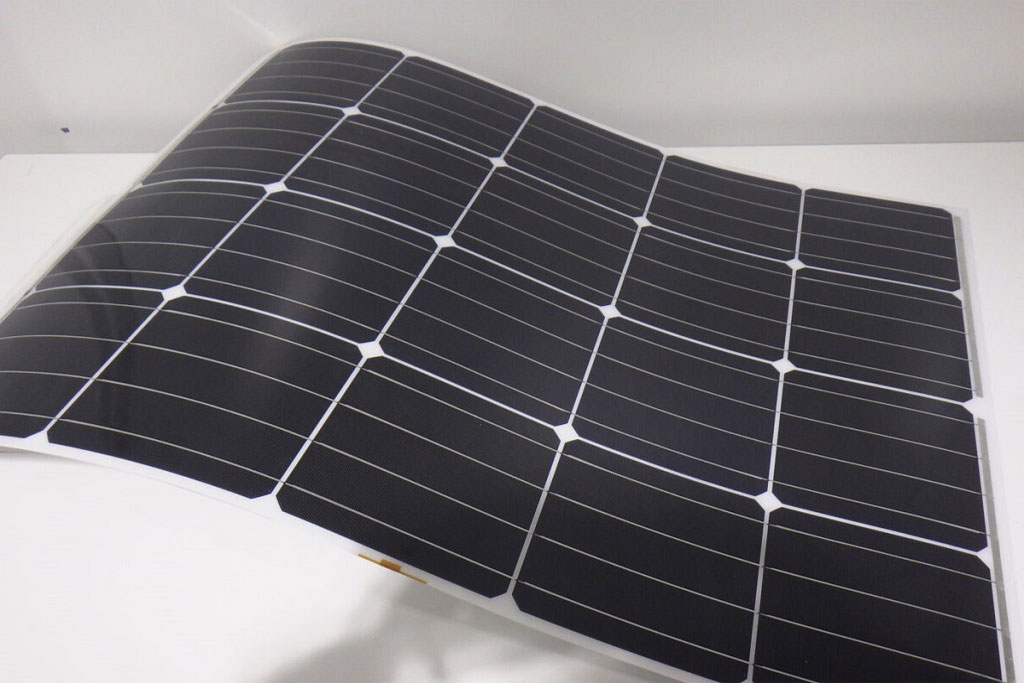

Flexibility

Flexibility is a crucial factor, especially in applications where solar panels need to conform to curved or irregular surfaces.

ETFE solar panels excel in this regard, offering high flexibility and durability. This makes them ideal for installations where rigid panels might be impractical.

PET solar panels are also flexible, but they generally exhibit less flexibility compared to ETFE counterparts.

Transparency and Efficiency

Transparency is essential for maximizing the absorption of sunlight and, consequently, the efficiency of solar panels.

ETFE solar panels boast high transparency levels, reaching up to 95%. This exceptional transparency ensures that a significant portion of sunlight penetrates the panel, enhancing energy conversion.

PET solar panels, while moderately transparent, may not allow as much light to pass through as ETFE panels.

Durability

The durability of solar panels is crucial for long-term performance, especially in outdoor installations exposed to various weather conditions.

ETFE solar panels exhibit remarkable durability, providing resilience against chemicals and UV radiation. This renders them well-suited for use in challenging climates where prolonged exposure to sunlight and environmental elements is unavoidable.

PET solar panels also demonstrate good durability, but they may experience degradation over time, particularly in environments with high UV exposure.

Temperature Resistance

Solar panels are subjected to a wide range of temperatures, and their ability to withstand these fluctuations is vital.

ETFE panels exhibit a wide temperature tolerance, making them appropriate for use in both warm and cold environments..

PET solar panels also have moderate temperature resistance, although they may not perform as well as ETFE panels in extreme temperature conditions.

Weight

The weight of solar panels is a critical consideration, especially in applications where weight is a limiting factor, such as on rooftops or lightweight structures.

ETFE solar panels are known for their lightweight nature, reducing the overall load on structures and enabling more versatile installation options.

PET solar panels are also relatively lightweight, making them suitable for various applications without imposing excessive structural demands.

Cost

Cost is a significant factor influencing the adoption of solar panels.

ETFE solar panels, with their advanced material properties, they have a higher price than PET solar panels. However, the potential benefits in terms of performance and durability may justify the initial investment.

PET solar panels are generally more cost-effective, making them an attractive option for budget-conscious projects.

Applications

ETFE panels, with their high flexibility and durability, are well-suited for installations where conforming to irregular surfaces is necessary. They are commonly used in lightweight, flexible, and curved installations, offering architects and designers more flexibility in integrating solar technology into their projects.

PET solar panels find applications in less demanding scenarios, where the emphasis may be on cost-effectiveness rather than advanced features.

Maintenance

Low maintenance requirements are desirable for solar panels to ensure consistent performance over their lifespan.

Due to their durable and resistant nature, ETFE solar panels generally have low maintenance needs than PET solar panels.

Environmental

As the world embraces renewable energy, the environmental impact of materials used in solar panels becomes a focal point. Both ETFE and PET are recyclable, contributing to sustainability efforts.

Conclusion

The choice between ETFE and PET solar panels depends on the specific requirements of each project.

ETFE panels offer high flexibility, transparency, and durability, making them ideal for applications where advanced features are essential.

On the other hand, PET panels provide a cost-effective solution with good efficiency, suitable for less demanding scenarios.