Plastics have become an integral part of various industries, playing a crucial role in the manufacturing of products ranging from packaging materials to advanced engineering components. When it comes to selecting the right type of plastic for a specific application, two broad categories often come into consideration: universal plastics and special engineering plastics.

Universal Plastics

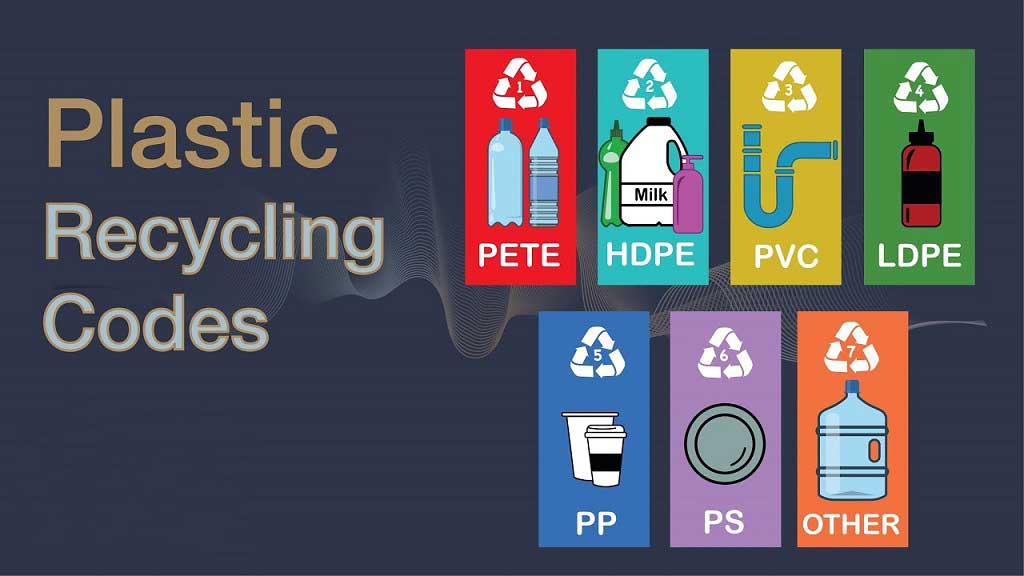

Universal plastics, often referred to as commodity plastics, are widely used in everyday products due to their cost-effectiveness and versatility. Examples of universal plastics include polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and (PS). These recyclable plastic materials are known for their ease of processing, wide availability, and affordability, making them suitable for applications such as packaging, containers, and consumer goods.

Universal Plastics Comparison

Property | PET | HDPE | PVC | LDPE | PP | PS |

Chemical Structure | (C10H8O4)n | (CH2-CH2)n | (C2H3Cl)n | (CH2-CH2)n | (C3H6)n | (C8H8)n |

Density (g/cm³) | 1.38 | 0.95 | 1.38 - 1.45 | 0.92 - 0.94 | 0.89 - 0.91 | 1.04 - 1.06 |

Melting Point (°C) | 250 | 120 | 212 | 105 | 160 | 240 |

Transparency | Transparent | Translucent to opaque | Translucent to opaque | Transparent | Transparent | Transparent to translucent |

Flexibility | Rigid | Flexible | Rigid | Flexible | Rigid | Rigid |

Tensile Strength (MPa) | 50 - 80 | 20 - 37 | 45 - 65 | 7 - 13 | 25 - 40 | 50 - 75 |

Chemical Resistance | Resistant to weak acids | Resistant to most chemicals | Resistant to acids and bases | Resistant to most chemicals | Resistant to most chemicals | Resistant to most chemicals |

Recycling Code | #1 | #2 | #3 | #4 | #5 | #6 |

Common Uses | Beverage bottles, fibers | Bottles, containers, pipes | Pipes, cable insulation | Plastic bags, film | Containers, packaging | Disposable cutlery, packaging |

PET

PET is a versatile thermoplastic, commonly used in beverage bottles, and food packaging. It is recyclable and lightweight. Its excellent barrier properties make it suitable for preserving the freshness of various products, while its durability ensures widespread application in industries seeking a balance between functionality and sustainability.

HDPE

HDPE is a robust, lightweight plastic with high chemical resistance, making it ideal for containers, pipes, and packaging. Recognized for its durability and ability to withstand harsh environmental conditions, HDPE is widely used in industries such as agriculture, construction, and healthcare. Its recyclability contributes to its eco-friendly profile.

PVC

PVC is recognized for its durability, chemical resistance, and fire-retardant properties. Commonly employed in construction, healthcare, and consumer goods. Its rigid and flexible forms make it suitable for an array of applications.

LDPE

LDPE has excellent resistance to moisture and chemicals. Widely used in packaging, LDPE’s flexibility makes it suitable for squeeze bottles, films, and disposable gloves. Its recyclability and energy efficiency contribute to its popularity in industries focused on reducing environmental impact.

PP

PP is a durable, heat-resistant plastic widely used in packaging, textiles, and automotive components. Known for its strength and flexibility, PP is a preferred choice for containers, caps, and various consumer goods. Its ability to endure high temperatures makes it appropriate for items that are safe for use in microwaves, adding to its versatility.

PS

PS is a lightweight, rigid plastic with excellent insulation properties, commonly used in disposable food service items, packaging, and consumer electronics. Its versatility extends to both solid and foam forms, providing solutions for diverse applications. While its recyclability is a consideration, advancements in sustainable alternatives continue to shape its role in the market.

Special Engineering Plastics

On the other hand, special engineering plastics, also known as high-performance plastics, are designed to meet specific requirements that universal plastics may not adequately address. Examples of special engineering plastics include polyether ether ketone (PEEK), Polyimide (PI), polytetrafluoroethylene (PTFE), polyphenylene sulfide (PPS), Polyetherimide (PEI) and polyamide-imide (PAI). These plastics often possess unique characteristics, such as high-temperature resistance, exceptional strength, chemical resistance, flame retardancy, or specific electrical properties. They are chosen for applications demanding high strength, resistance to chemicals, and superior thermal stability.

Special Engineering Plastics Comparison

Property | PEEK | PI | PTFE | PPS | PEI | PAI |

Temperature Resistance | Up to 260°C | Up to 300°C | Up to 260°C | Up to 240°C | Up to 170-180°C | Up to 260°C |

Chemical Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

Mechanical Strength | High | High | Low to Moderate | High | High | Very High |

Wear Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

Electrical Insulation | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

Flame Resistance | Good | Excellent | Excellent | Excellent | Good | Excellent |

Creep Resistance | Good | Excellent | Good | Excellent | Excellent | Excellent |

Dimensional Stability | Excellent | Excellent | Excellent | Good | Excellent | Excellent |

Cost | High | High | Moderate to High | Moderate | High | High |

PEEK

PEEK is a high-performance thermoplastic known for exceptional mechanical strength, chemical resistance, and thermal stability. Widely used in demanding applications, such as aerospace and medical devices, PEEK maintains its integrity under extreme conditions, making it an ideal choice for critical components.

PI

PI, or Polyimide, is a versatile engineering plastic prized for its excellent heat resistance, electrical insulating properties, and dimensional stability. Commonly used in the electronics industry, PI is vital for manufacturing flexible circuits, insulation films, and high-temperature-resistant components.

PTFE

PTFE, or Teflon, is a non-stick and low-friction engineering plastic renowned for its chemical inertness and high-temperature resistance. Widely employed in applications such as gaskets, seals, and bearings, PTFE’s unique properties make it indispensable in industries ranging from chemical processing to food production.

PPS

PPS stands out as an advanced engineering plastic renowned for its outstanding chemical resistance, flame retardant properties, and dimensional stability. Commonly used in automotive, electrical, and aerospace applications, PPS exhibits strength at elevated temperatures and withstands harsh environments, making it a preferred material for demanding engineering solutions.

PEI

PEI is a durable engineering plastic recognized for its high heat resistance, dimensional stability, and flame-retardant properties. Widely utilized in the aerospace, electronics, and automotive industries, PEI’s ability to maintain strength at elevated temperatures and resistance to chemicals make it an ideal material for various demanding applications.

PAI

PAI is a high-performance engineering plastic prized for its exceptional strength, thermal stability, and chemical resistance. Commonly employed in aerospace, automotive, and electronics, PAI’s combination of mechanical properties and resistance to harsh environments make it a reliable choice for critical components in demanding engineering applications.

Conclusion

The choice between universal plastics and special engineering plastics depends on the specific application performance requirements. Universal plastics are versatile and cost-effective for general use, while special engineering plastics are tailored for demanding environments where superior properties are essential.